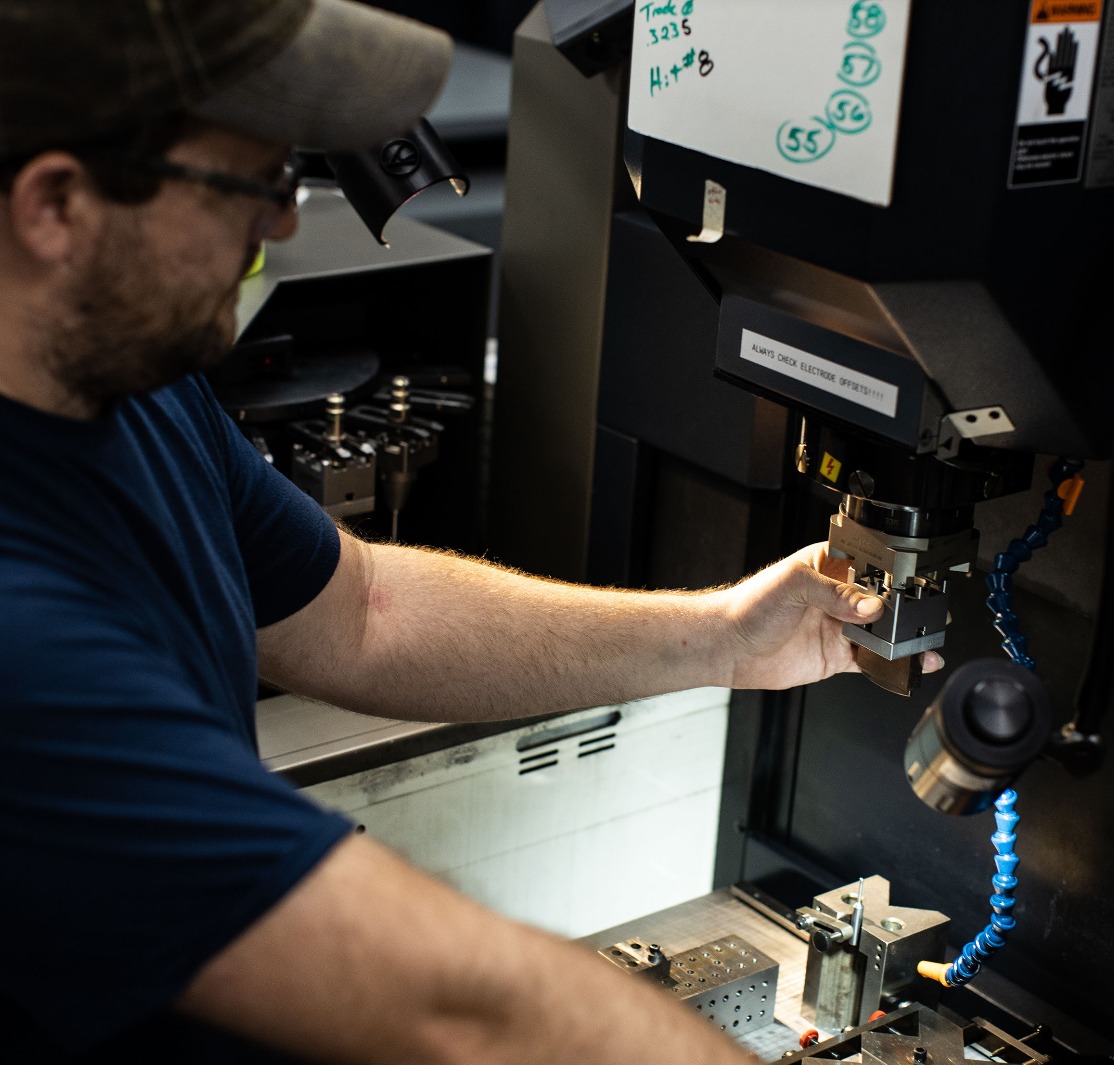

Working at JV Manufacturing

We consider ourselves “the Designers and Builders of the better carbide dies.” That’s because we continually invest in the people and the technology that allow us to set the industry standard in all that we do. If you’re just as passionate as we are, consider joining us. JV Manufacturing Co., Inc. is an equal opportunity manufacturing company that will not discriminate on the basis of race, color, national origin, sex, and handicap in its employment practices. EEO employer.