RESULTS FOR OUR CUSTOMERS

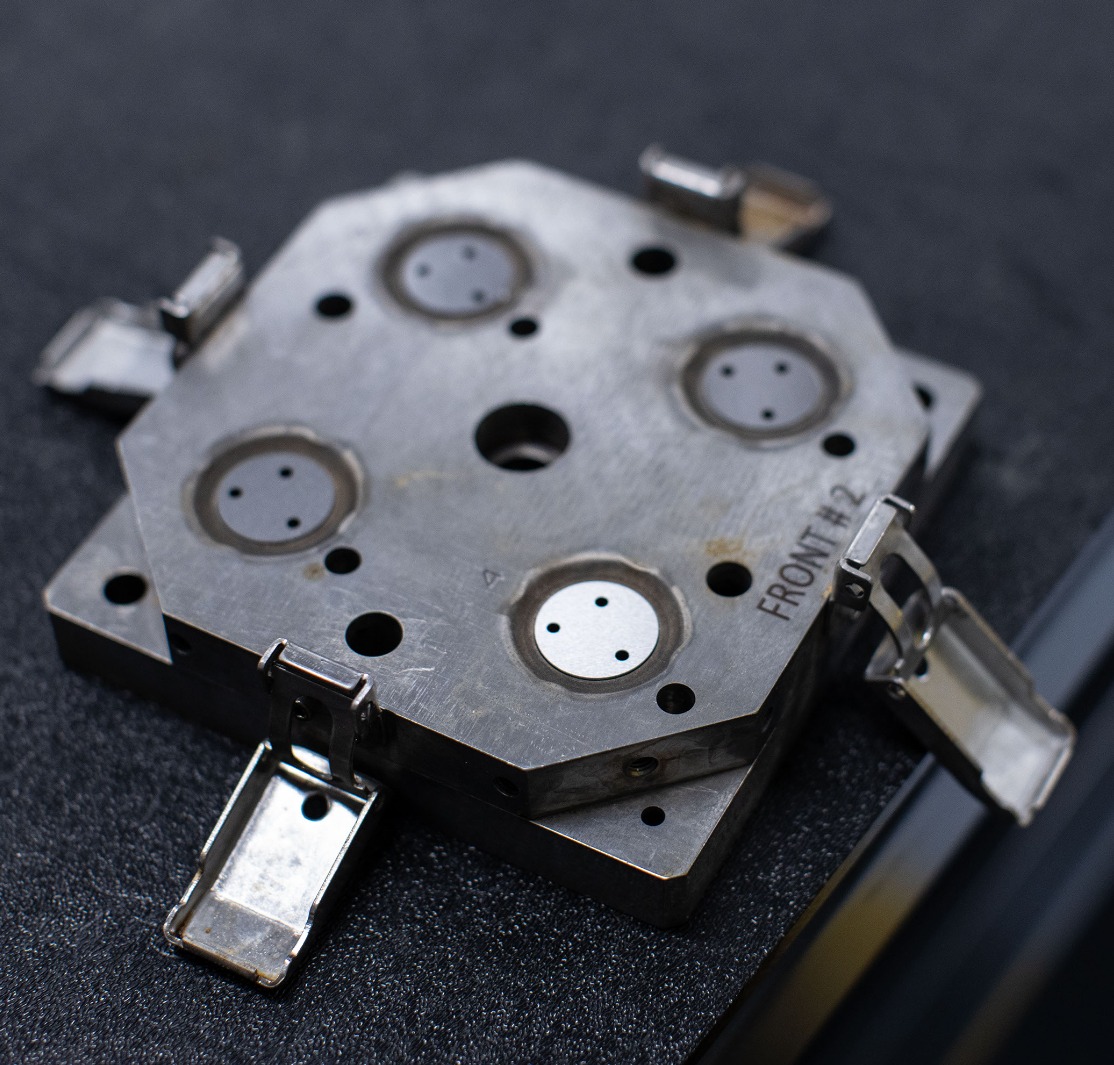

The result is a burr-free part without thermal or mechanical stresses, micro-cracks, white layers, or electrode wear. Each PEM Machine has been engineered to pair perfectly with a PEM Aqua electrolyte processing/supply unit, a PEM Power generator unit, and a PEM Control operator station – all perform in tandem for the ultimate in precision.

Our typical tolerances range from 0.0001”-0.0005”. We currently serve in these markets: Automotive, Aerospace, Medicine, Punching & Forming, and Coining & Embossing.

Contact us