Think about your production goals. For low volumes, simple dies get the job done; for high-output efficiency, go with progressive dies. Complex parts? Compound or progressive dies are your best bet. And don’t forget your material—tough metals need tough tooling.

Beginner's Guide to Stamping

Whether you're new to manufacturing or considering outsourcing your production needs, this beginner's guide covers everything you need to know about stamping. From understanding basic processes to learning about precision techniques and quality assurance, this comprehensive guide is your ultimate resource.

In a rush? Download the eBook to access the guide anytime.

- Section I What is Stamping? An Introduction to the Process

- Section II The Benefits of Stamping

- Section III How Does Metal Stamping Work?

- Section IV Stamping Material Choices: Metal vs. Plastic

- Section V The Role of Quality Assurance in Metal Stamping

- Section VI Metal Stamping Types: An Overview of Die Stamping

- Section VII Types of Stamping Presses

- Section VIII Reducing Manufacturing Lead Time with Progressive Die Stamping

- Section IX Finding a Reputable Tool & Die Maker

- Chapter X Leave Your Mark with Stamping Excellence

Introduction to the Die Stamping Process

.webp?width=724&height=483&name=iStock-515788550%20(4).webp)

Stamping is a process that uses dies and presses to shape or cut materials into desired forms. It’s a versatile and cost-effective method for producing high-quality, uniform parts at scale. Industries like automotive, aerospace, and electronics rely heavily on stamping to create components that meet strict standards.

Metal Stamping vs. Plastic Stamping

While metal stamping is more common, plastic stamping has become an efficient alternative for lightweight applications. Metal stamping is best suited for durable, high-strength parts, whereas plastic stamping is ideal for components that require corrosion resistance or reduced weight.

The Benefits of Stamping

When is Stamping Really Beneficial?

When high volumes, tight tolerances, and repeatability are key, stamping becomes the clear winner over other manufacturing processes like machining, laser cutting, or casting.

Some core benefits of stamping include:

1. High Precision and Consistency

- Stamping produces uniform parts with tight tolerances, ensuring high precision across large production volumes.

- Advanced dies and presses minimize variability, resulting in consistent quality for every part.

2. Cost Efficiency

- Stamping reduces material waste by optimizing the use of raw materials.

- High-speed stamping processes lower production costs, especially for large-scale operations.

- Tooling, while an initial investment, enables significant cost savings over time.

3. Scalability for High-Volume Production

- Stamping is ideal for producing millions of identical parts quickly and efficiently.

- Progressive dies and automated presses further enhance scalability, meeting the demands of mass production.

4. Versatility in Design

- Stamping can accommodate various designs, from simple to highly complex shapes.

- The process works with various materials, including metals, plastics, and composites.

- Intricate designs are achievable through precision tooling and advanced press technologies.

5. Durability and Strength

- Stamped parts maintain the strength of the base material, ensuring durability and reliability.

- Processes like deep drawing and embossing add additional structural integrity to components.

How Does Metal Stamping Work?

Now that we have defined stamping, let's explore how it really works.

Metal stamping involves transforming raw materials into finished parts through a series of well-defined steps:

- Material Selection: The process starts by selecting materials based on their properties, such as strength, ductility, and corrosion resistance.

- Tool and Die Design: Custom tools and dies are designed to shape or cut the material according to specific product requirements.

- Pressing: High-powered presses apply force to the material, shaping it into the desired form. Mechanical, hydraulic, or servo presses are used based on the complexity of the part.

- Trimming and Finishing: Excess material is removed, and parts are polished or treated for final use.

- Quality Assurance: Each part undergoes inspection and testing to ensure it meets design tolerances and performance standards.

This structured process ensures high precision and efficiency in producing large quantities of components while minimizing waste and maximizing quality.

How Does Plastic Stamping Differ from Metal Stamping?

While the overall process of plastic stamping is similar to metal stamping, there are notable differences:

- Material Properties: Plastics are more pliable than metals, requiring less force during stamping. This allows for finer, more intricate designs.

- Tooling Adjustments: Dies used in plastic stamping may need specialized coatings to reduce wear and prevent sticking.

- Applications: Plastic stamping is ideal for lightweight parts, such as medical device components or electronic casings, where corrosion resistance is key.

Understanding these differences helps manufacturers decide between metal and plastic stamping based on project requirements.

Stamping Material Choices: Metal vs. Plastic

Metal stamping is a cornerstone of manufacturing, providing durable and precise components for various industries. Its versatility, cost-effectiveness, and ability to produce high-volume parts make it indispensable. Here are some of the most impactful applications of metal stamping:

Automotive Industry

Metal stamping plays a critical role in the automotive sector, producing components such as:

- Engine Parts: Precision-stamped brackets, pistons, and housings ensure reliability and performance.

- Chassis Components: Structural parts like cross-members and frames provide safety and durability.

- Body Panels: Stamping produces smooth, uniform panels for vehicle exteriors, ensuring aesthetic appeal and aerodynamics.

Aerospace Industry

The demand for lightweight yet durable components in aerospace makes metal stamping essential. Applications include:

- Airframe Parts: Precision-stamped brackets and panels reduce aircraft weight while maintaining structural integrity.

- Engine Components: High-strength stamped parts withstand extreme temperatures and pressures.

- Seating and Interiors: Custom-stamped metal parts improve passenger safety and comfort.

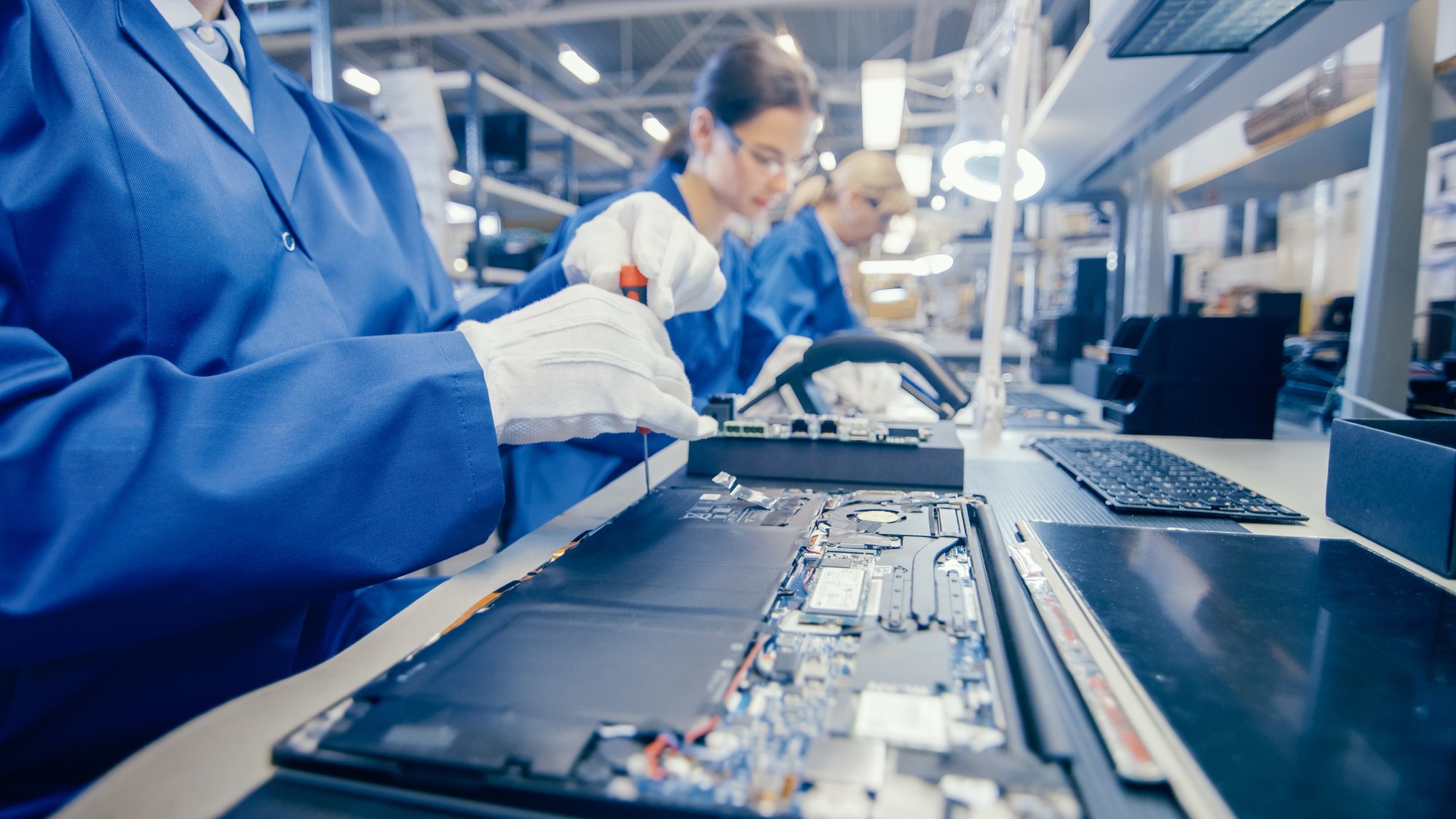

Electronics Industry

The electronics sector relies on metal stamping for:

- Connectors: Precision-stamped connectors ensure reliable electrical performance.

- Shielding Components: Metal shields protect sensitive electronics from electromagnetic interference (EMI).

- Casings: Durable, lightweight housings for smartphones, laptops, and cameras.

Other Industries

- Industrial Equipment: Stamping produces gears, fasteners, and housings for heavy machinery.

- Energy Sector: Metal-stamped components are used in renewable energy systems like wind turbines and solar panels.

- Medical Devices: High-precision stamped parts ensure the reliability and safety of surgical tools and diagnostic equipment.

Common Applications of Plastic Stamping

Plastic stamping caters to industries where lightweight, cost-effective, and corrosion-resistant components are essential.

- Electronics: Plastic casings, connectors, and insulative components are staples in the electronics industry due to their lightweight and non-conductive properties.

- Medical Devices: Plastic stamping is integral in the healthcare sector, from disposable instruments to durable housing for diagnostic equipment.

- Automotive: Lightweight plastic parts help reduce vehicle weight, improving fuel efficiency and reducing emissions.

- Packaging: Custom plastic stamping creates durable, lightweight, and recyclable packaging solutions.

Why Metal Stamping Is a Preferred Manufacturing Method

Precision: Ensures tight tolerances for high-quality components.

Cost-Effectiveness: Reduces material waste and speeds up production cycles.

Metal stamping’s adaptability and precision make it a go-to manufacturing process for industries requiring high-quality, reliable parts.

The Role of Quality Assurance in Metal Stamping

Quality assurance (QA) ensures that every stamped part meets design and performance standards. This process is critical in maintaining customer trust, minimizing defects, and ensuring compliance with industry regulations. Common QA practices include:

- Visual Inspection: Checking for surface defects such as cracks, burrs, or irregularities.

- Dimensional Testing: Verifying that parts meet precise measurements using tools like calipers and coordinate measuring machines (CMMs).

- Performance Testing: Assess parts' strength, durability, and functionality to ensure they perform as intended under operational conditions.

- Material Analysis: Conducting metallurgical tests to verify that materials meet required specifications.

The Importance of QA in High-Stakes Industries

Industries like aerospace, automotive, and electronics demand rigorous quality assurance due to the critical nature of their components. A single defect can lead to operational failures, making QA an indispensable part of stamping.

Leveraging Technology for QA

Modern QA systems often incorporate advanced technologies such as:

- Automated Inspection Systems: High-speed cameras and sensors detect defects in real time.

- Data Analytics: Tracking trends in defect rates to identify root causes and improve processes.

- Digital Twins: Simulating parts and processes to predict potential issues before production begins.

Implementing robust QA systems builds trust with customers and ensures regulatory compliance.

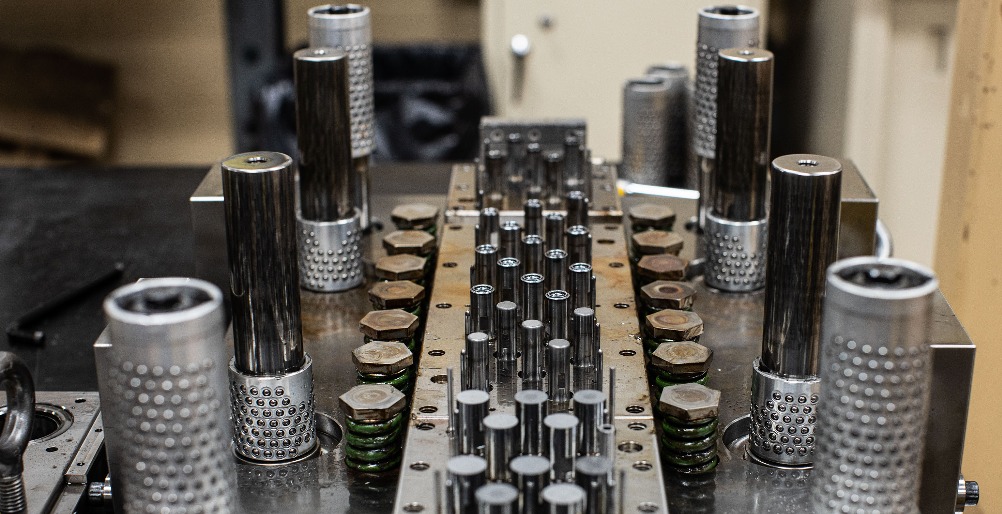

Metal Stamping Types: An Overview of Die Stamping

To take metal stamping one step further, let's discuss a specific type - die stamping.

Die stamping is a versatile and efficient manufacturing process that shapes materials like metal, plastic, and composites into precise parts and components. Known for its ability to produce high volumes of identical parts with consistent quality, die stamping is a cornerstone in the automotive and electronics industries.

How Does Die Stamping Work?

The die stamping process involves several key steps:

- Design and Creation of Dies: Dies made from high-strength materials, such as carbide or tool steel, are crafted to withstand the pressures of stamping.

- Material Feeding: Sheet metal or other materials are fed into the stamping press manually or automatically, depending on production needs.

- Stamping: The press applies force to the die, cutting, bending, or shaping the material into its final form.

- Ejection: Completed parts are removed, and the process repeats for the next piece.

-Enhanced-NR.jpg?width=2000&height=1333&name=dies%20(20)-Enhanced-NR.jpg)

Types of Die Stamping

| Progressive Die Stamping | Combines multiple operations into one continuous process, making it ideal for complex, high-volume production. |

| High-Speed Stamping | Suited for simpler designs produced at rapid speeds, this type is perfect for large-scale operations. |

| Sheet Metal Stamping | Focuses on forming parts from sheet metal, which is widely used in the automotive and aerospace industries. |

| Plastic Stamping | Similar to metal stamping but designed for lightweight, corrosion-resistant plastic parts. |

| Carbide Dies | Built for durability in high-wear applications, these dies ensure precision over extended production runs. |

| Programmable Die Stamping | Allows configurable operations within each stroke, offering flexibility for intricate designs. |

Advantages of Die Stamping

The advantages of die stamping include:

- High Efficiency: Quickly produces large quantities of parts.

- Cost-Effectiveness: Minimizes waste and reduces labor costs.

- Precision: Achieves tight tolerances and consistent quality.

- Versatility: Adapts to various materials and complex designs.

Die stamping plays a pivotal role in modern manufacturing, combining speed, accuracy, and adaptability to meet the demands of diverse industries. Businesses can optimize their production strategies and achieve superior results by understanding their processes and types.

Exploring the Types of Stamping Dies and Their Functions

Stamping dies are the tools that give shape and definition to stamped parts. Each die type serves a unique purpose in production, ensuring that components meet specific design and performance requirements. Here are the most common types:

Single Station Dies

These dies perform one task per press stroke, such as cutting or punching, making them perfect for simple parts and low-volume production. They're easy to use but inefficient for high-output manufacturing.

Blanking Dies

Used to cut raw material into base shapes called blanks, these dies are great for clean, repeatable cuts in high-volume settings. They minimize waste but may require extra finishing on the edges.

Piercing Dies

These dies create holes or slots in sheet metal, commonly used in precision industries like aerospace. They deliver burr-free holes but demand frequent upkeep with tough materials.

Compound Dies

Capable of performing multiple actions like cutting and punching in one press stroke, these are ideal for intricate parts in electronics or medical devices. They boost efficiency but come with higher upfront costs.

Multi Station (Progressive) Dies

These dies carry out several operations across different stations during one cycle, perfect for large-scale production. They’re highly consistent but require significant setup and skilled operators.

Transfer Dies

These dies transfer parts from station to station, performing distinct operations at each, ideal for complex or oversized parts. While flexible, they tend to be slower than progressive systems.

When Choosing a Die...

Not sure what fits best? Reach out to JV Manufacturing—we’ll help you choose the right tool for the job.

Types of Stamping Presses: The Backbone of Stamping

Stamping presses provide the force needed to shape and cut materials in the stamping process. Each type of press offers unique advantages, making them suitable for specific applications.

Here’s an in-depth look at the common types of stamping presses and their advantages and limitations.

Mechanical Stamping Presses

Mechanical presses use a flywheel and crankshaft mechanism to store and transfer energy, delivering high-speed, repetitive force.

Mass Production

Fixed Setup

High-Speed Operations

Design Restrictions

Sleek Design

Limited Capabilities

Hydraulic Stamping Presses

Utilize hydraulic cylinders to generate force, offering consistent pressure throughout the stroke.

Precise & Accurate

Relatively Slower

Adaptable and Flexible

Necessary Ongoing Maintenance

Handles Complexities

Not Suitable for Mass Production

Servo-Driven Stamping Presses

Powered by servo motors, these advanced presses allow programmable motion and precise control.

Precise & Intricate

Large Investment

Improved Accuracy

Skilled-Technicians Needed

Eco-Friendly Operation

Longer Setup Time

Reducing Manufacturing Lead Time with Progressive Die Stamping

Progressive die stamping is a highly efficient manufacturing process that helps businesses save time and resources by performing multiple operations in a single pass. Here's how this method reduces lead time and enhances production efficiency:

Key Benefits of Progressive Die Stamping

- Consolidated Operations:

- Progressive die stamping combines multiple actions—cutting, bending, and forming—into one seamless process.

- This eliminates the need for separate setups and transitions between stations, significantly reducing production time.

- Higher Production Speed:

- The process is automated and continuous with progressive dies, enabling manufacturers to produce parts at high speeds without compromising quality.

- This makes it ideal for large-volume orders where time-to-market is critical.

- Reduced Material Waste:

- The precision of progressive dies ensures that materials are used efficiently, minimizing scrap and optimizing yield.

- This lowers material costs and shortens the time needed for additional trimming or adjustments.

- Enhanced Consistency:

- Progressive die stamping ensures uniformity across all parts by performing all operations in a controlled, automated environment.

- This reduces the need for rework or quality checks, saving valuable production hours.

Applications Where Time Savings Matter

Progressive die stamping is especially valuable in industries where speed and efficiency are paramount:

- Automotive: Producing high-volume components such as brackets, clips, and housings.

- Electronics: Manufacturing precise connectors and casings at scale.

- Aerospace: Creating lightweight parts quickly to meet strict timelines.

Considerations for Implementation

To fully leverage the time-saving benefits of progressive die stamping, businesses should consider:

- Tooling Quality: Investing in high-quality progressive dies to ensure durability and precision.

- Machine Compatibility: Ensuring presses can handle progressive dies' requirements.

- Production Planning: Aligning production schedules with the capabilities of this high-speed process.

By adopting progressive die stamping, manufacturers can significantly reduce lead times, enhance efficiency, and improve their ability to meet market demands.

Finding a Reputable Tool & Die Maker

Selecting the right tool and die maker is one of the most critical steps in ensuring the success of your stamping projects. A reliable partner can make all the difference in quality, efficiency, and long-term cost savings. Here are the key factors to consider:

1. Proven Expertise and Industry Experience

- Look for a tool and die maker with a solid track record in your industry.

- Ask for examples of previous projects to assess their capability to meet your requirements.

- Verify certifications or qualifications that demonstrate expertise in die-making and stamping processes.

2. State-of-the-Art Capabilities

- Ensure they use modern equipment and advanced technologies, such as CAD/CAM software, for designing complex dies.

- To streamline production, check whether they offer in-house capabilities like heat treatment, precision grinding, or secondary operations.

3. Customization and Design Support

- A reputable tool and die maker will collaborate with you during the design phase, offering recommendations to improve manufacturability and reduce costs.

- Look for providers specializing in custom solutions tailored to your specific stamping needs.

4. Quality Assurance Processes

- Inquire about their quality assurance systems, including inspection protocols, testing methods, and certifications (e.g., ISO standards).

- A robust QA program ensures that each tool and die meets precise tolerances and performance standards.

5. Production Capacity and Lead Times

- Assess whether their production capacity aligns with your project timelines and volume requirements.

- Ask about their typical lead times and ability to scale production if demand increases.

6. Transparent Communication and Customer Support

- Effective communication is vital. Choose a partner who is responsive, collaborative, and willing to keep you informed at every stage of the project.

- Ensure they offer post-delivery support, such as maintenance services or repairs, to extend the life of your tooling.

7. Cost vs. Value

- While cost is a significant factor, focus on overall value rather than just the lowest price.

- Evaluate their pricing concerning the quality of materials, durability of the tooling, and potential savings in production efficiency.

Questions to Ask When Evaluating a Tool & Die Maker

- What industries do you specialize in?

- Can you provide case studies or references from similar projects?

- What quality assurance measures do you have in place?

- Do you offer ongoing support and maintenance for tools and dies?

- How do you handle design changes or urgent production needs?

Choosing the right tool and die maker is an investment in the success of your manufacturing process. By focusing on expertise, capabilities, and communication, you can ensure a partnership that delivers high-quality results and supports your business’s growth. Take the time to research and evaluate potential partners carefully to make the best decision for your stamping needs.

Leave Your Mark with Stamping Excellence

.jpg?width=724&height=483&name=iStock-1424921227%20(1).jpg)

Stamping is a cornerstone of modern manufacturing, offering precision, scalability, and efficiency. Partnering with a trusted provider ensures your production goals are met with expertise and innovation. Explore how stamping can elevate your manufacturing strategy today.

%201.png?width=146&height=103&name=Slice%203%20(72)%201.png)

.webp?width=2122&height=1412&name=The%20Solid%206%20Types%20of%20Stamping%20Dies%20(1).webp)